Product Description

Product Description

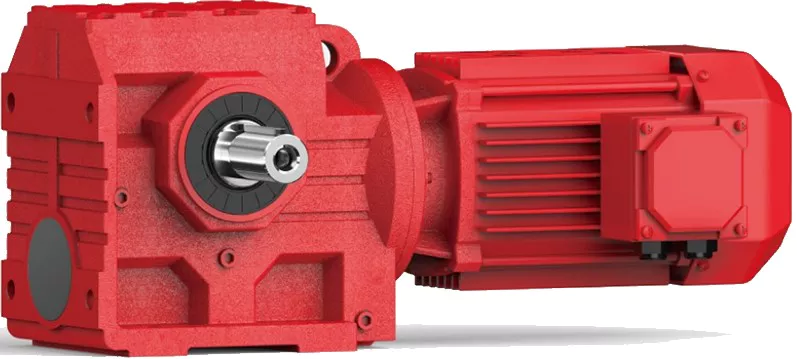

Introducing FR,FF, FK, and FS Series Gear Reducers and Gearmotors

Our FR, FF, FK, and FS series gear motors are designed to meet a vast spectrum of industrial requirements. These series are distinguished by their remarkable compactness, minimal noise output, high load-bearing capacity, low energy consumption, superior torque transmission, optimal efficiency, minimal temperature rise, and extended lifespan.

Customized Solutions for Diverse Needs

Embracing a philosophy of modular design and optimization, we are dedicated to fulfilling diverse customer needs across various applications. Multi-stage gear motors with additional helical gear input stages are supplied to achieve particularly low output speeds.

Advanced Material and Manufacturing Techniques

Gears and pinions are crafted from premium alloy steel, treated with carburization and quenching for enhanced durability. The high-precision gear grinding process, complemented by meticulous tooth profile modifications, guarantees a smooth transmission.

Versatile Installation and Output Options

Our gear reducers are designed for various mounting configurations including foot, flange, and torque arm installations. Output shaft options are versatile, offering both CZPT and hollow shafts that can be adapted using either spline or locking disc connections for a secure and efficient power transfer.

Comprehensive Input Compatibility

Besides the integral connection with motor directly, CZPT also provide AM motor flanges compliant with IEC, NEMA C faces compliant with Nema system, and AD CZPT shaft input.

Company Profile

We would like to introduce ourselves as:

The largest manufacturer and exporter of worm gear reducers in Asia.

Established in 1976, we transformed from a county owned factory to private 1 in 1996. HangZhou SINO-DEUTSCH POWER TRANSMISSION EQUIPMENT CO.,LTD is our new name since 2001.

We are the first manufacturer of reducers and gearboxes in China who was given export license since year 1993.

“Fixedstar” brand gearboxes and reducers are the first owner of CHINA TOP BRAND and Most Famous Trade Mark for reducers.

First to achieve ISO9001 and CE Certificate among all manufacturers of gearboxes in China.

As a professional manufacturer of worm gearbox and worm gear reducers in China, we mainly produce reduction gearbox,aluminum case worm gearboxes,arc gear cylindrical worm gearboxes, worm gear reducers, in line helical gearboxes, and cyclo drive reducers, etc. These products feature rational structure, stable performance, and reliable quality, and so on. They are widely used in power, mining, metallurgy, building material, chemical, food, printing, ceramic, paper-making, tobacco, and other industries.

We have 600 workers in our factory, which covers 70,000 square CZPT in HangZhou. We have been making 2,500 units of reducers everyday since 2012. We are proudly exporting 70% of our products to more than 40 countries all over the word. Our customers come from Italy, Germany, USA, Canada, Spain, UK, Mexico, Brazil, Argentina, Turkey, Singapore and other main industrial countries in the world. 30% of them are OEM made for direct manufacturers of other products.

We warmly welcome customers from other parts of the world to visit us. Seeing is believing. We are very confident that after visiting our facility, you will have confidence on our products. We have the latest automatic equipments and experienced workers to ensure the stable quality and large output. We have the most sophisticated technical and engineering team to support most demanding requirement on standard and OEM products.

Looking CZPT to meeting you in HangZhou, China.

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Application: | Machinery, Marine, Agricultural Machinery, Industry |

|---|---|

| Function: | Distribution Power, Change Drive Torque, Change Drive Direction, Speed Changing |

| Layout: | Parallel |

| Hardness: | Hardened Tooth Surface |

| Installation: | Horizontal Type |

| Step: | Double-Step |

| Customization: |

Available

| Customized Request |

|---|

Key Factors for Selecting a Helical Gearbox

Choosing the right helical gearbox for an application involves considering several key factors:

- Load and Torque: Evaluate the maximum load and torque requirements to ensure the gearbox can handle the application’s demands.

- Speed Range: Determine the required speed range and ensure the gearbox’s gear ratios can accommodate it.

- Efficiency: Helical gearboxes are known for their high efficiency. Select a gearbox with efficiency ratings that meet your application’s needs.

- Space Constraints: Consider the available installation space and choose a compact gearbox that fits within the available dimensions.

- Mounting Position: The mounting position affects lubrication, cooling, and overall performance. Ensure the gearbox is suitable for the desired mounting orientation.

- Service Life: Choose a gearbox with a service life that matches your application’s expected lifespan.

- Backlash: Evaluate the allowable backlash, which affects precision and positioning accuracy.

- Noise and Vibration: Assess the acceptable noise and vibration levels and choose a gearbox with suitable characteristics.

- Environmental Conditions: Consider factors like temperature, humidity, and dust levels to ensure the gearbox can operate reliably in the application environment.

- Maintenance: Factor in maintenance requirements and choose a gearbox with manageable maintenance needs.

- Cost: Balance performance with budget constraints to find a gearbox that offers the best value for your application.

By carefully evaluating these factors, you can select a helical gearbox that optimally meets your application’s requirements and ensures efficient and reliable operation.

Relationship Between Helix Angle and Load Capacity in Helical Gears

The helix angle of helical gears plays a significant role in determining their load-carrying capacity and overall performance. Here’s the relationship between the helix angle and load capacity:

1. Load Distribution: The helix angle affects how the load is distributed along the gear teeth. A larger helix angle results in a more gradual tooth engagement, allowing for smoother load sharing across multiple teeth. This improves the gear’s ability to handle higher loads.

2. Contact Ratio: The contact ratio, which indicates the number of teeth in contact at any given time, increases with a larger helix angle. A higher contact ratio helps distribute the load over a larger area of the gear teeth, enhancing load-carrying capacity.

3. Tooth Meshing: The helix angle affects how the teeth mesh with each other. A higher helix angle promotes gradual and smoother meshing, reducing the concentration of stress on individual teeth. This results in improved resistance to wear and fatigue.

4. Axial Thrust: Helical gears produce axial thrust due to their helical nature. This thrust can affect the gear’s ability to handle radial loads. Proper consideration of the helix angle can help manage axial thrust and prevent overloading.

5. Lubrication: The helix angle affects the lubrication conditions between gear teeth. A larger helix angle may allow better oil flow and lubrication, reducing friction and wear, thereby enhancing load capacity.

6. Noise and Vibration: The helix angle also influences noise and vibration levels in helical gears. Optimal helix angle selection can minimize noise and vibration, contributing to smoother operation and prolonged gear life.

Optimal Helix Angle Selection: While a larger helix angle generally increases load capacity, it’s important to strike a balance. Extremely large helix angles can lead to reduced tooth strength and efficiency. Engineers consider factors like application requirements, tooth strength, and noise considerations when selecting the optimal helix angle for a specific gear design.

The relationship between the helix angle and load capacity underscores the importance of proper gear design to ensure optimal performance, durability, and reliability in various applications.

Limitations and Disadvantages of Helical Gear Systems

While helical gear systems offer numerous advantages, they also come with certain limitations and disadvantages:

- Axial Thrust: Helical gears generate axial thrust due to the helix angle of the teeth. This thrust can cause additional load on bearings and may require additional measures to counteract.

- Complex Manufacturing: The manufacturing process for helical gears is more complex than that of straight-toothed gears, which can lead to higher production costs.

- Axial Length: Helical gears require more axial space compared to spur gears with the same gear ratio. This can be a limitation in applications with space constraints.

- Sliding Contact: Helical gears have sliding contact between their teeth, which can result in higher friction and more heat generation compared to rolling contact gears.

- Efficiency: Although helical gears are generally efficient, their efficiency can be slightly lower than that of some other gear types, especially at high speeds.

- Complexity in Gearbox Design: The inclination of helical gear teeth introduces additional complexity in gearbox design and alignment.

- Reverse Thrust: In some cases, reverse thrust can occur when helical gears are subjected to high axial loads, leading to undesirable effects.

It’s important to consider these limitations and disadvantages when selecting gear systems for specific applications. Despite these challenges, helical gears remain a popular choice in various industries due to their benefits and overall performance characteristics.

editor by CX 2024-05-07