Product Description

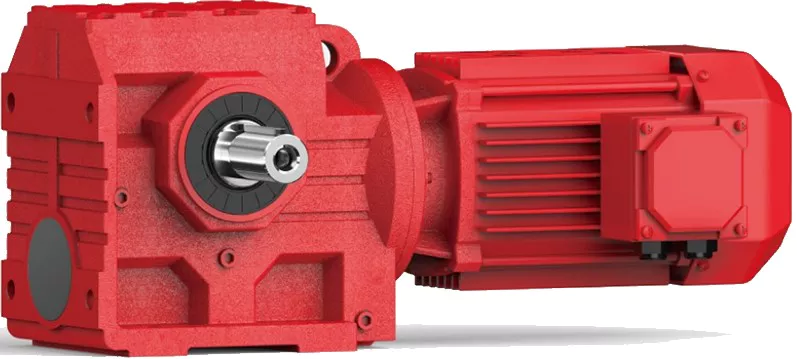

GH Series Helical Inline Gearmotor foot mount inline gear reducer Helical Gearbox

Components:

1. Housing: Aluminium alloy

2.Gears: Coaxial Gears, 1 stage

3. Input Configurations:Solid Input Shaft,Motor Flange – IEC B5

4. Output Configurations:Solid Output Shaft

Features:

Models & Variants:

GH Horizontal Type Palte 3-Phase(Brake)Motor

GV Vertical Type Palte 3-Phase(Brake) Motor

GH Horizontal Type Light Palte 3-Phase(Brake)Motor

GV Vertical Type Light Duty Palte 3-Phase(Brake)Motor

GH Horizontal Type High Ratio Type Palte 3-Phase(Brake)Motor

GV Vertical Type High Ratio Type Palte 3-Phase(Brake)Motor

GH Horizontal Type High Ratio Type Light Duty Palte 3-Phase(Brake)Motor

GV Vertical Type High Ratio Type Light Duty Palte 3-Phase(Brake)Motor

GH Horizontal Type Palte 1-Phase(Brake)Motor

GV Vertical Type Palte 1-Phase(Brake)Motor

GH Horizontal Type Light Duty Palte 1-Phase(Brake)Motor

GV Vertical Type High Ratio Light Duty Palte 1-Phase(Brake)Motor

GHM Horizontal Type Flange Type Reducer Without Motor

GVM Vertical Type Flange Type Reducer Without Motor

GHM Horizontal Type High Ratio Flange Type Reducer Without Motor

GVM Vertical Type High Ratio Flange Type Reducer Without Motor

GHD Horizontal Type Double Shaft Type Reducer Without Motor

GVD Vertical Type Double Shaft Type Reducer Without Motor

GHD Horizontal Type Double Shaft High Ratio Type Reducer Without Motor

GVD Vertical Type Double Shaft High Ratio Type Reducer Without Motor

GV Vertical Type Palte 3-Phase(Brake)Motor -2#Code B Type Flange

GV..S Iec Vertical 3-Phase Alluminum(Brake)Motor

GV..S Vertical 3-Phase Alluminum(Brake)Motor

GV..S Vertical 3-Phase Alluminum(Brake)Motor–B14

| Power | Output Shasft | Type | |||

| Lubricant(L) | Weight(Kg) | ||||

| GH | GV | GH | GV | ||

| 0.1KW 1/8HP |

∅18 | 0.19 | 0.18 | 5.6 | 5.8 |

| ∅22 | 0.38 | 0.39 | 7.3 | 7.3 | |

| ∅28 | 0.8 | 0.85 | 14.6 | 14.6 | |

| 0.2KW 1/4HP |

∅18 | 0.17 | 0.18 | 7.0 | 8.0 |

| ∅22 | 0.38 | 0.39 | 8.6 | 8.8 | |

| ∅28 | 0.63 | 0.68 | 11.0 | 10.8 | |

| ∅32 | 1.30 | 1.40 | 27.6 | 28.0 | |

| 0.4KW 1/2HP | ∅22 | 0.38 | 0.39 | 11.2 | 11.2 |

| ∅28 | 0.63 | 0.68 | 14.2 | 14.0 | |

| ∅32 | 0.95 | 1.05 | 27.0 | 26.9 | |

| ∅40 | 1.80 | 1.90 | 46.0 | 47.0 | |

| 0.75KW 1HP |

∅28 | 0.63 | 0.68 | 15.0 | 15.0 |

| ∅32 | 0.95 | 1.05 | 27.6 | 28.0 | |

| ∅40 | 1.26 | 1.38 | 42.3 | 41.9 | |

| ∅50 | 3.0 | 3.13 | 91.5 | 91.5 | |

| 1.5KW 2HP |

∅32 | 0.95 | 1.05 | 33.6 | 34.6 |

| ∅40 | 1.47 | 1.59 | 49.6 | 49.0 | |

| ∅50 | 2.52 | 2.60 | 94.0 | 94.0 | |

| ∅50 | 3.47 | 3.65 | 105 | 106 | |

| 2.2KW 3HP |

∅40 | 1.68 | 1.80 | 53.0 | 55.0 |

| ∅50 | 2.52 | 2.60 | 92.5 | 88.5 | |

| 3.7KW 5HP |

∅40 | 1.68 | 1.80 | 64.0 | 66.0 |

| ∅50 | 2.52 | 2.60 | 98.5 | 94.5 | |

Packaging & Delivery

Speed Reducer Helical Gearbox Packaging Details:Plastic Bags, Plywood Cases

Port:ZheJiang /HangZhou

About Us

- More than 35 years experience in R&D and manufacturing, export gear motors & industrial gearboxes.

- . Standardization of the gearbox series

- Strong design capability for large power & customized gearboxes.

- High quality gearboxes and proven solutions provider.

- Strict quality control process, stable quality.

- Less than 2% of the quality complaints.

- Modular design, short delivery time.

- Quick response & professional services.

A high product quality, a wide production and a flexible structure are the strong points of AOKMAN . AOKMAN was founded in 1982, specialized in R & D and manufacturing of gearboxes, gears, shaft, motor and spare parts.

FAQ

1. What information shall we give before placing a purchase order?

a) Type of the gearbox, ratio, input and output type, input flange, mounting position, and motor information etc.

b) Housing color.

c) Purchase quantity.

d) Other special requirements.

2.What industries are your gearboxes being used?

Our gearboxes are widely used in the areas of textile, food processing, beverage, chemical industry,escalator,automatic storage equipment, metallurgy, environmental protection, logistics and etc.

3.How long is your delivery time?

Generally it is 7-20 days if the goods. or it is over 20 days if the goods are custom-made.

4. What is your terms of payment ?

30% Advance payment by T/T after signing the contract.70% before delivery

5.Do you have any supporting products?

Yes, we can also provide matching reducer or motor

/* March 10, 2571 17:59:20 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Application: | Machinery |

|---|---|

| Function: | Speed Reduction |

| Layout: | Helical |

| Hardness: | Hardened Tooth Surface |

| Installation: | Horizontal Type |

| Step: | Three-Step |

| Customization: |

Available

| Customized Request |

|---|

Key Factors for Selecting a Helical Gearbox

Choosing the right helical gearbox for an application involves considering several key factors:

- Load and Torque: Evaluate the maximum load and torque requirements to ensure the gearbox can handle the application’s demands.

- Speed Range: Determine the required speed range and ensure the gearbox’s gear ratios can accommodate it.

- Efficiency: Helical gearboxes are known for their high efficiency. Select a gearbox with efficiency ratings that meet your application’s needs.

- Space Constraints: Consider the available installation space and choose a compact gearbox that fits within the available dimensions.

- Mounting Position: The mounting position affects lubrication, cooling, and overall performance. Ensure the gearbox is suitable for the desired mounting orientation.

- Service Life: Choose a gearbox with a service life that matches your application’s expected lifespan.

- Backlash: Evaluate the allowable backlash, which affects precision and positioning accuracy.

- Noise and Vibration: Assess the acceptable noise and vibration levels and choose a gearbox with suitable characteristics.

- Environmental Conditions: Consider factors like temperature, humidity, and dust levels to ensure the gearbox can operate reliably in the application environment.

- Maintenance: Factor in maintenance requirements and choose a gearbox with manageable maintenance needs.

- Cost: Balance performance with budget constraints to find a gearbox that offers the best value for your application.

By carefully evaluating these factors, you can select a helical gearbox that optimally meets your application’s requirements and ensures efficient and reliable operation.

Materials Used in Manufacturing Helical Gears

Helical gears are commonly manufactured using a variety of materials to meet specific requirements for strength, durability, wear resistance, and other mechanical properties. Some of the materials commonly used for manufacturing helical gears include:

- Steel: Various types of steel, such as carbon steel, alloy steel, and stainless steel, are frequently used due to their high strength, durability, and wear resistance. They are suitable for a wide range of applications and provide excellent performance.

- Cast Iron: Cast iron gears are known for their cost-effectiveness and good wear resistance. They are often used in applications where heavy loads and moderate speeds are involved.

- Brass: Brass gears are chosen for applications that require quiet operation and low-speed applications. They offer good corrosion resistance and are commonly used in smaller machinery.

- Bronze: Bronze gears are valued for their excellent wear resistance and compatibility with lubricants. They are often used in heavy-duty applications and situations where high loads are encountered.

- Plastics and Polymers: Certain plastic materials, such as nylon and acetal, are used for gears that require low noise levels and resistance to chemicals and corrosion. They are suitable for applications where lightweight components are essential.

- Aluminum: Aluminum gears are lightweight and corrosion-resistant, making them suitable for applications where weight reduction and corrosion resistance are priorities.

The choice of material depends on factors such as the application’s load, speed, environment, and desired performance characteristics. Manufacturers select materials that best align with the specific requirements of the helical gear system, ensuring optimal function and longevity.

Lubrication Requirements for Maintaining Helical Gearboxes

Lubrication is essential for the proper functioning and longevity of helical gearboxes. The lubrication requirements include:

- Viscosity: Selecting a lubricant with the appropriate viscosity is crucial. The viscosity should provide sufficient lubrication and ensure a protective film between gear teeth under varying operating conditions.

- Extreme Pressure (EP) Properties: Helical gears often experience high contact pressures. Lubricants with EP additives form a protective barrier that prevents metal-to-metal contact and reduces wear.

- Oil Additives: Anti-wear additives, antioxidants, and corrosion inhibitors enhance the lubricant’s performance and protect gears from wear and degradation.

- Frequent Inspections: Regularly inspect the lubricant’s condition to detect contamination, degradation, or depletion. Scheduled oil analysis can help monitor the health of the lubricant.

- Proper Lubricant Application: Ensure the gearbox is properly filled with the correct amount of lubricant. Follow manufacturer recommendations for lubricant type and quantity.

- Lubricant Change Intervals: Establish regular lubricant change intervals based on operating conditions. Extreme conditions or heavy loads may require more frequent changes.

Appropriate lubrication minimizes friction, wear, and heat generation, leading to improved efficiency, reduced maintenance, and extended gearbox life. It’s crucial to follow the manufacturer’s guidelines and consult with lubrication experts to select the right lubricant and maintenance practices for your specific helical gearbox application.

editor by CX 2024-02-21