Product Description

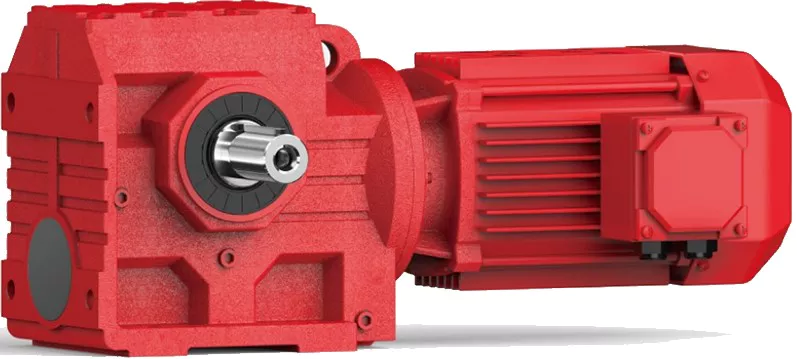

R Series Inline Helical 2 double stage Speed Reducer output 30 rpm Gearbox

Product Description

>Click Here To Cotact<

Product Advantages

Company Information

Certificate

Main Products

Global Exhibition

|

Brand |

WUMA |

|

|

|

|||

|

Housing |

Three type |

|

|

|

|||

|

Nameplate |

WUMA or Customize |

|

|

|

|||

|

Reducer |

worm gearbox,helical gearbox, hypoid gearbox,planetary gearbox and variator etc. |

|

|

|

|||

FAQ

1 . How to choose a gearbox which meets our requirement?

You can refer to our catalogue to choose the gearbox or we can help to choose when you provide

the technical information of required output torque, output speed and motor parameter etc.

2. What information shall we give before placing a purchase order?

a) Type of the gearbox, ratio, input and output type, input flange, mounting position, and motor informationetc.

b) Housing color.

c) Purchase quantity.

d) Other special requirements.

3. What industries are your gearboxes being used?

Our gearboxes are widely used in the areas of textile, food processing, beverage, chemical industry,

escalator,automatic storage equipment, metallurgy, tabacco, environmental protection, logistics and etc.

4. Doyou sell motors?

We have stable motor suppliers who have been coperating with us for a long-time. They can provide motors

with high quality.

>Return Home<

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Application: | Motor, Machinery, Agricultural Machinery |

|---|---|

| Hardness: | Hardened Tooth Surface |

| Installation: | Vertical Type |

| Customization: |

Available

| Customized Request |

|---|

.shipping-cost-tm .tm-status-off{background: none;padding:0;color: #1470cc}

|

Shipping Cost:

Estimated freight per unit. |

about shipping cost and estimated delivery time. |

|---|

| Payment Method: |

|

|---|---|

|

Initial Payment Full Payment |

| Currency: | US$ |

|---|

| Return&refunds: | You can apply for a refund up to 30 days after receipt of the products. |

|---|

Advancements in Helical Gearbox Technology

Advancements in helical gearbox technology have led to improved performance, efficiency, and versatility. Here are some notable advancements:

- Material Innovations: The use of advanced materials, such as high-strength alloys and composites, has enhanced the durability and load-carrying capacity of helical gears. These materials also contribute to reduced weight and improved efficiency.

- Precision Manufacturing: Modern manufacturing techniques, including CNC machining and gear grinding, have enabled the production of helical gears with higher accuracy and tighter tolerances. This results in smoother operation and reduced noise levels.

- Gear Tooth Profile Optimization: Advanced computer simulations and modeling techniques allow for the optimization of gear tooth profiles. This results in better load distribution, reduced stress concentration, and improved overall gearbox efficiency.

- Lubrication and Cooling: Improved lubrication systems and cooling mechanisms help maintain optimal operating temperatures and extend the lifespan of helical gearboxes. This is particularly important for high-demand applications.

- Noise and Vibration Reduction: Innovative designs and precision manufacturing techniques have led to helical gears with reduced noise and vibration levels. This advancement is crucial for industries where noise reduction is a priority.

- Compact Design: Advancements in gear design and manufacturing have allowed for more compact and lightweight helical gearbox configurations, making them suitable for space-constrained environments.

- Integration with Electronics: Some modern helical gearboxes are designed for seamless integration with electronic control systems. This enables better monitoring, control, and optimization of gearbox performance.

- Customization: Advancements in manufacturing and design tools allow for greater customization of helical gearboxes to meet specific application requirements. This includes adapting gear ratios, sizes, and configurations.

In summary, advancements in helical gearbox technology have led to enhanced performance, durability, efficiency, and customization options. These innovations continue to make helical gearboxes a versatile and reliable choice for a wide range of industrial applications.

Relationship Between Helix Angle and Load Capacity in Helical Gears

The helix angle of helical gears plays a significant role in determining their load-carrying capacity and overall performance. Here’s the relationship between the helix angle and load capacity:

1. Load Distribution: The helix angle affects how the load is distributed along the gear teeth. A larger helix angle results in a more gradual tooth engagement, allowing for smoother load sharing across multiple teeth. This improves the gear’s ability to handle higher loads.

2. Contact Ratio: The contact ratio, which indicates the number of teeth in contact at any given time, increases with a larger helix angle. A higher contact ratio helps distribute the load over a larger area of the gear teeth, enhancing load-carrying capacity.

3. Tooth Meshing: The helix angle affects how the teeth mesh with each other. A higher helix angle promotes gradual and smoother meshing, reducing the concentration of stress on individual teeth. This results in improved resistance to wear and fatigue.

4. Axial Thrust: Helical gears produce axial thrust due to their helical nature. This thrust can affect the gear’s ability to handle radial loads. Proper consideration of the helix angle can help manage axial thrust and prevent overloading.

5. Lubrication: The helix angle affects the lubrication conditions between gear teeth. A larger helix angle may allow better oil flow and lubrication, reducing friction and wear, thereby enhancing load capacity.

6. Noise and Vibration: The helix angle also influences noise and vibration levels in helical gears. Optimal helix angle selection can minimize noise and vibration, contributing to smoother operation and prolonged gear life.

Optimal Helix Angle Selection: While a larger helix angle generally increases load capacity, it’s important to strike a balance. Extremely large helix angles can lead to reduced tooth strength and efficiency. Engineers consider factors like application requirements, tooth strength, and noise considerations when selecting the optimal helix angle for a specific gear design.

The relationship between the helix angle and load capacity underscores the importance of proper gear design to ensure optimal performance, durability, and reliability in various applications.

Helical Gearbox: Overview and Working Mechanism

A helical gearbox is a type of mechanical device used to transmit power and motion between rotating shafts. It employs helical gears, which are cylindrical gears with teeth that are cut at an angle to the gear axis. This design feature gives helical gearboxes their distinctive helical shape and provides several advantages in terms of efficiency, smoothness, and load-bearing capabilities.

The working mechanism of a helical gearbox involves the interaction of helical gears, which mesh together to transmit torque and motion. Here’s how it works:

- Gear Tooth Engagement: When power is applied to the input shaft of the gearbox, the helical gear on the input shaft meshes with the helical gear on the output shaft.

- Helical Angle: The helical angle of the gear teeth causes a gradual engagement between the teeth, resulting in a smooth and quiet meshing process compared to straight-cut gears.

- Torque Transfer: As the input gear rotates, it transfers rotational force (torque) to the output gear through the meshing of their helical teeth.

- Direction of Rotation: Depending on the arrangement of the helical gears, the output shaft’s direction of rotation can be the same as or opposite to that of the input shaft.

- Load Distribution: The helical design allows for multiple teeth to be engaged at any given moment, distributing the load more evenly across the gears. This results in higher load-carrying capacity and reduced wear on gear teeth.

- Efficiency: Helical gearboxes are known for their high efficiency due to the gradual tooth engagement and larger contact area, resulting in minimal energy loss as compared to other gear types.

Helical gearboxes find applications in various industries where smooth operation, high efficiency, and compact design are important. They are commonly used in machinery, conveyors, automotive transmissions, industrial equipment, and more.

editor by CX 2024-04-23